Capabilities

A “Turnkey” Service

Hochuen Medical provides turnkey service for IVD customers. The company can support customers from the R&D and prototyping phases to low and high-volume CMO manufacturing on microfluidic chips and biomedical consumables. The products include microfluidic kits, IVD disposables, POCT devices, DNA sequencing flowcells, life science research disposables, animal and plant disease detection kits, organ-on-a-chip, drug delivery, surgical devices, etc.

Our Capabilities

-

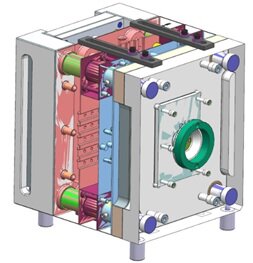

Injection molding

Hochuen medical owns more than 60 injection molding machines focusing on medical related devices in class 10k-100k clean rooms for…

-

In-house Mold Making

We have a large machine shop to make molds and fixture. Our turn-around of rapid prototype molds is 1 week, while production molds ...

-

Rapid Prototyping Mold

Prototyping injection molds can be made in Cu, Al, and steel with a leadtime of 1-2 weeks. A prototype low-grade steel mold can last for …

-

Cartridge Production

An integrated cartridge can consists of many different components (e.g., injection molded plastics, blister packs, die cut filters, etc)...

-

Manifold

-

Screen Printing

-

PCR Test

-

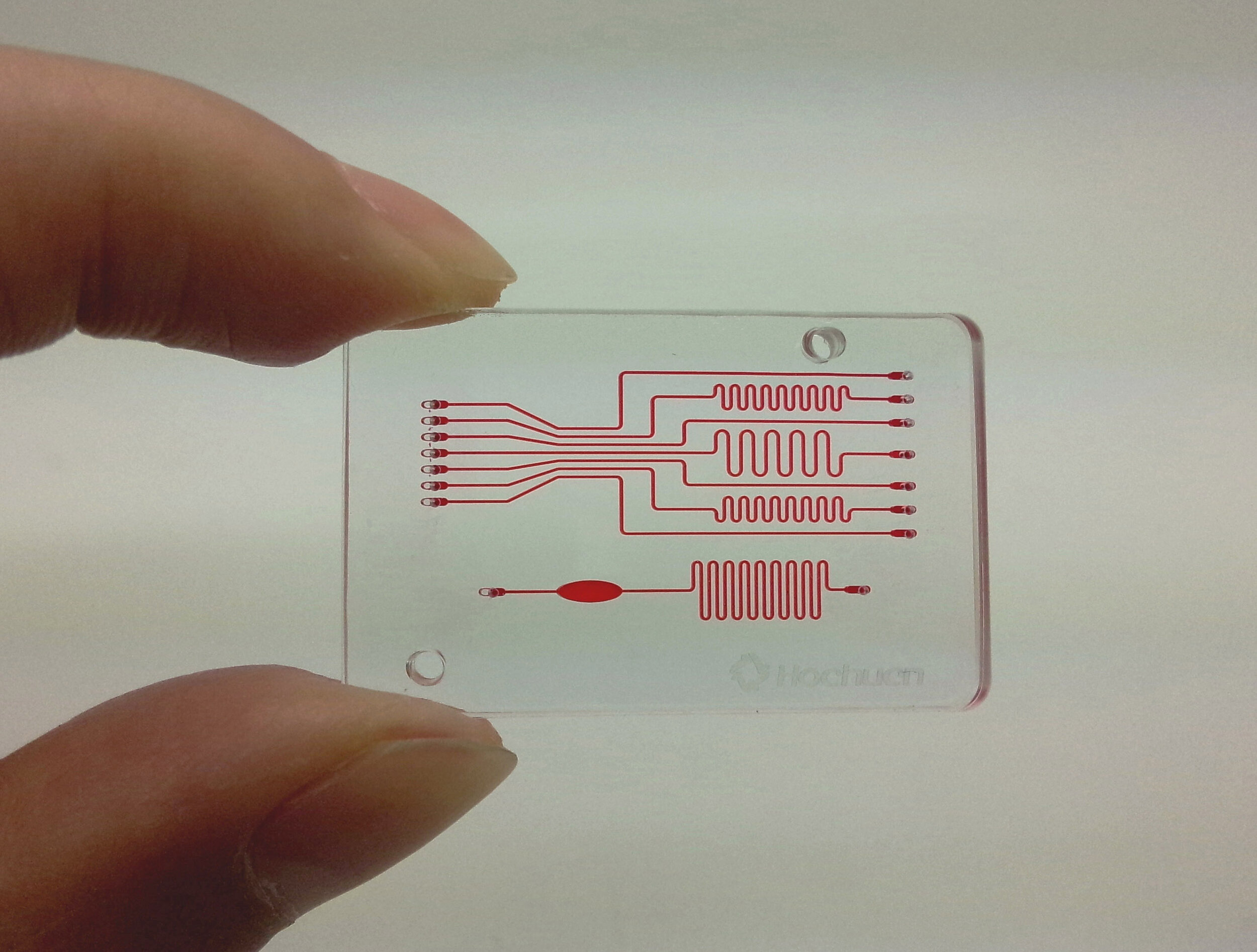

Microfluidics

-

Flat-Bed Die Cutting

-

Rotary Die Cutting

-

Laser Cutting

-

Bonding (Heat Staking)

-

Bonding (Clear to Black Laser Welding)

-

Bonding (Clear to Clear Plastic Laser Welding)

-

Bonding (Adhesive)

-

Bonding (Thermal Compression)

-

Bonding (Ultrasonic Welding)

-

Reagent Dispensing and Drying

-

Blister Pack

-

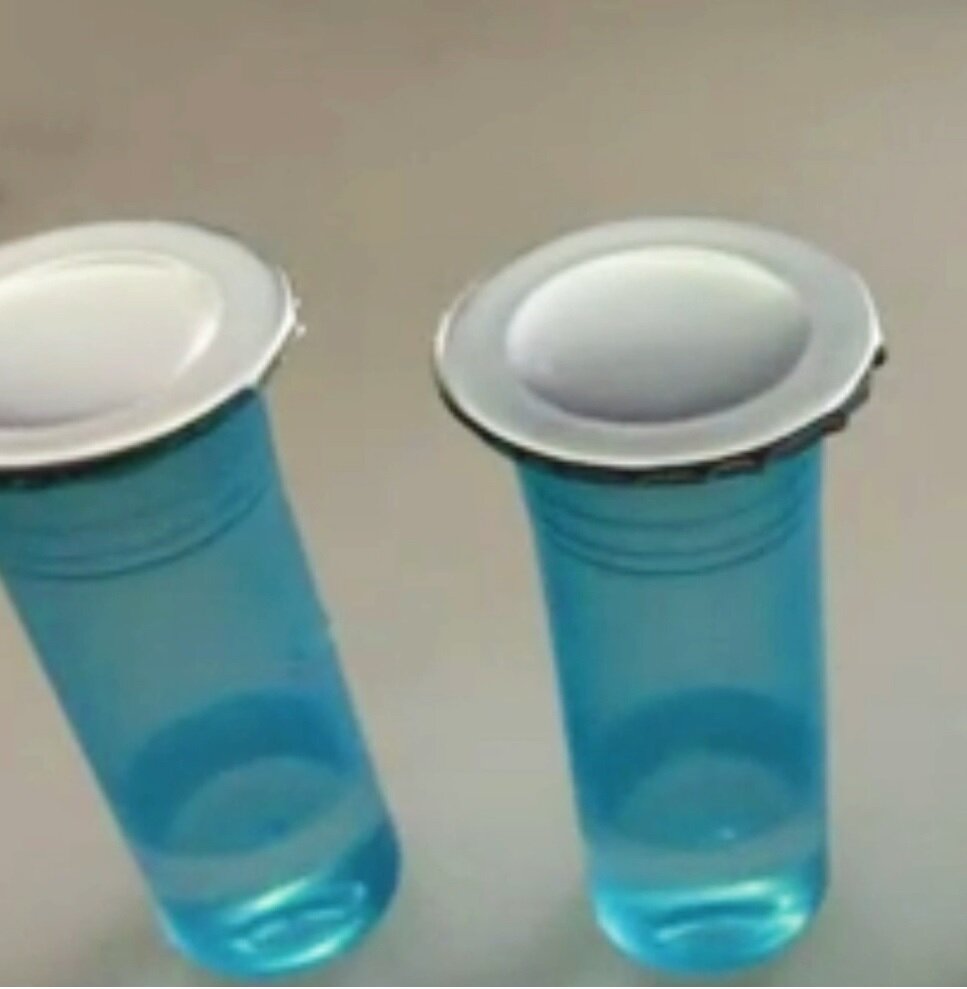

Buffer Cup

-

Dry Reagent (lyo beads) Handling

-

Reagent Formulation (GMP Rooms)

-

DNase and RNase Free Manufacturing

-

LSR

-

Overmolding

-

PDMS Microfabrication

-

Lamination

-

Plasma Surface Treatment

-

Packaging

-

QC

-

Fluorescence Imaging

-

Reagent Bottles

-

Low Volume Vials

-

Transfer pipettes

-

Sample Collection Bottle

-

Vials

-

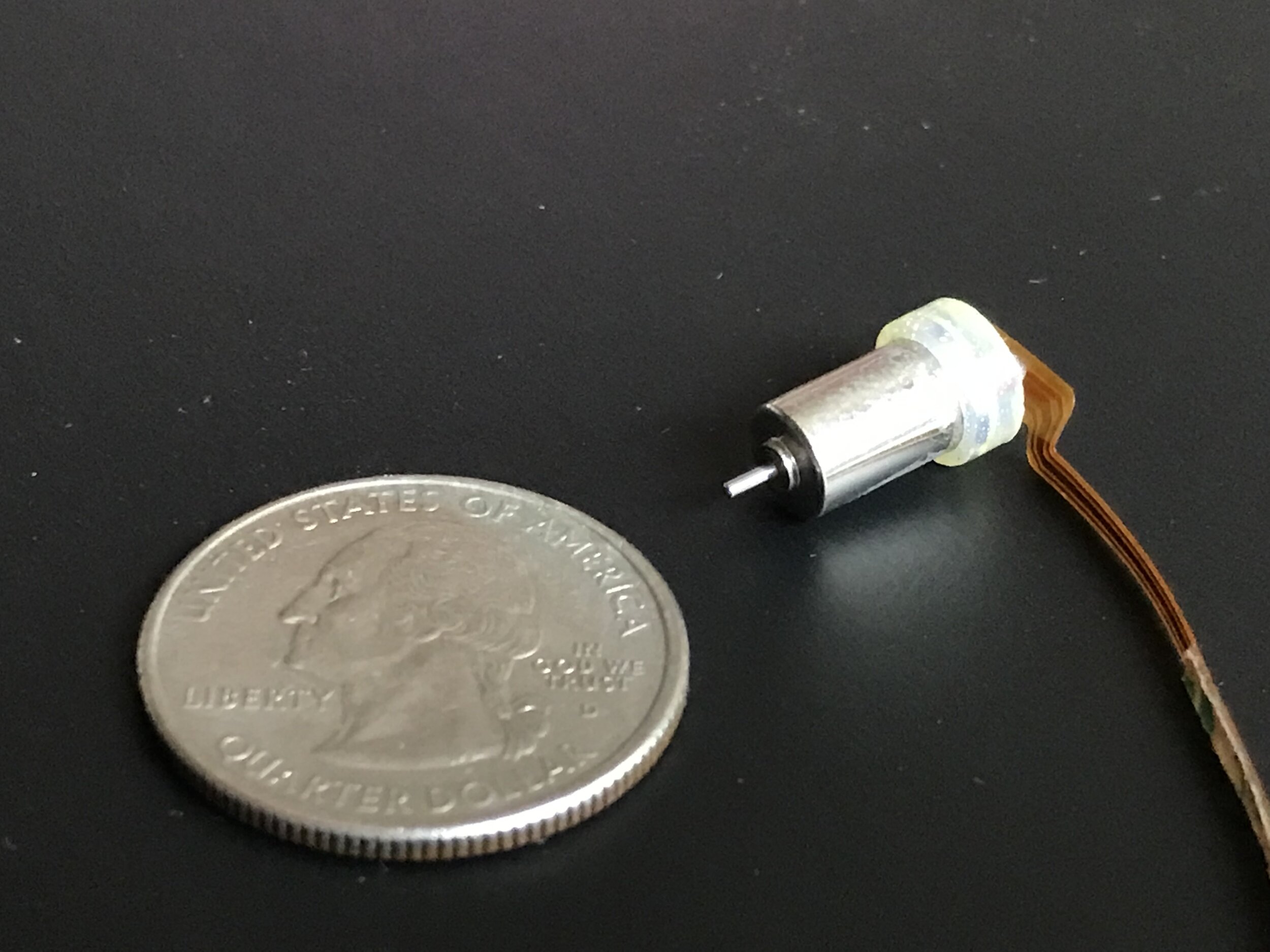

Micro Motor

-

Label Printing

-

Pad Printing

-

Surface hydrophobicity Treatment

-

Glass Chip Fabrication

-

Microtiter Plates

-

Reader/Instrument OEM